Recyclable aluminium

From design to end-of-life, ensuring high performance, recyclability, and minimal environmental impact.

- Increased lifespan

- A circular lifecycle

- Low Carbon Footprint Aluminium

Hydro CIRCAL® 75R, available as standard

Hydro CIRCAL® is the low-carbon aluminium alloy of our company, made with at least 75% recycled post-consumer scrap. This means the aluminium is sourced from end-of-life products, such as old facades or windows, which are recovered and recycled.

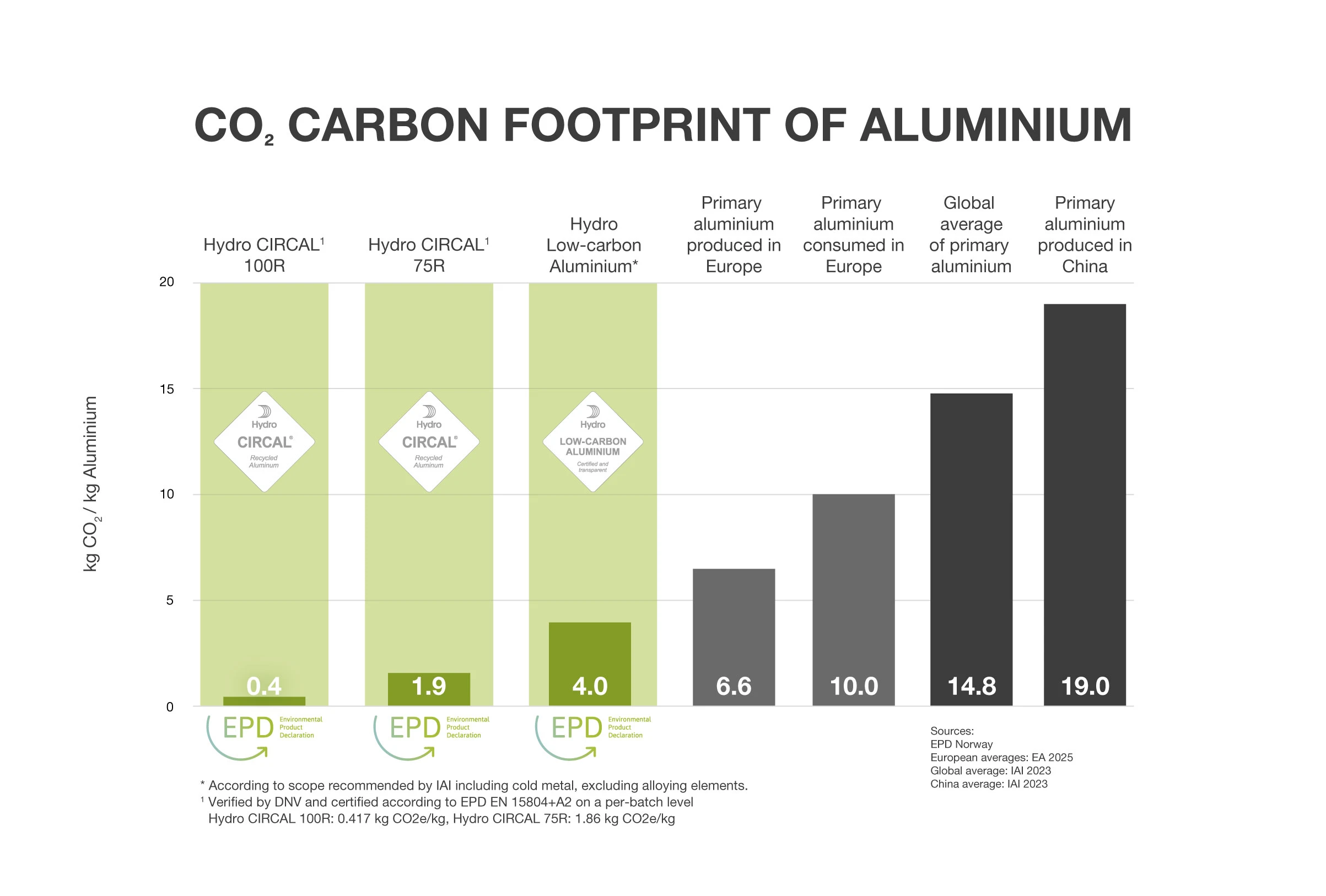

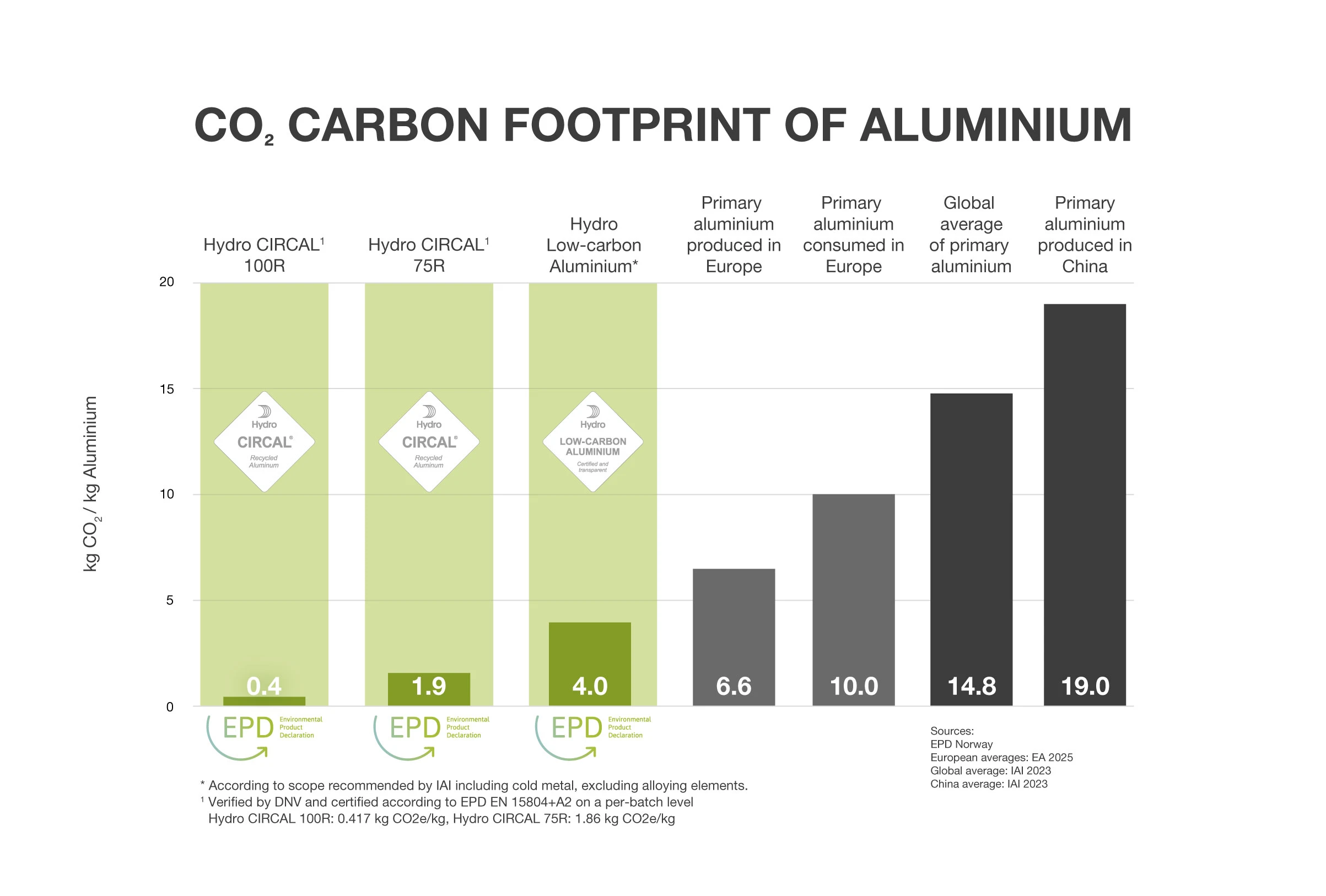

Hydro CIRCAL® 75R has a carbon footprint among the lowest in the world: 1.9 kg CO2e per kg of aluminium. Its carbon footprint is 80% of reduction vs the European primary average. The production and raw materials in Hydro CIRCAL® 75R can be traced on an individual batch level and is delivered with an Environmental Product Declaration and verification statement. With this low carbon aluminium, we can create high-quality, circular, and low-emission building products that meet the highest environmental standards.

Hydro CIRCAL® 100R, recycled at 100%, available on request

Hydro CIRCAL® 100R is a breakthrough in sustainable aluminium - made with 100% recycled post-consumer scrap. It's our most advanced material, designed for projects where circularity and carbon reduction are a priority.

With an independently verified carbon footprint of less than 0.5kg CO²e per kg of aluminium, Hydro CIRCAL® 100R offers a 97% reduction compared to the global average for primary aluminium (14.8kg CO²e). It delivers premium performance with one of the lowest carbon footprints available worldwide.

Due to the technical complexity and careful sourcing required, Hydro CIRCAL® 100R is currently produced in limited, on-demand batches - ideal for future-thinking projects aiming to meet the highest environmental standards.

Our windows and doors go beyond just aluminium. We carefully select suppliers who share our passion for quality and sustainability. Together, we create solutions that are perfect for your project.

A lower carbon footprint

Reducing the carbon footprint of buildings starts with their design and materials. Since a third of total CO₂ emissions occur during the use phase, the most effective way to cut operational emissions is by offering high-performance façade solutions that optimize energy use over time. That’s why we design façades that deliver exceptional thermal insulation, energy efficiency, acoustic comfort, and minimal maintenance.

But it doesn’t stop there—our new systems are made with at least 75% recycled and 95% recyclable content, and are built for circularity: easy to dismantle, reuse, and recycle at end of life. To go even further, we ensure our systems are produced within a responsible supply chain and certified by external organisations—providing maximum transparency and accountability.

By combining performance in use with low-impact, circular materials, our façades achieve a carbon footprint up to 70% smaller than comparable products.

WE RUN MORE SUSTAINABLE OPERATIONS

WE MANAGE THE END-OF-LIFE CIRCULARITY OF OUR MATERIALS

WE DESIGN DURABLE AND HIGH PERFORMING PRODUCTS

WE USE CIRCULAR MATERIALS

WE SUPPORT YOUR PROJECTS WITH THE RIGHT DIGITAL TOOLS

WE REDUCE THE FOOTPRINT OF OUR PRODUCTS

SAPA has the right solutions for a more sustainable building

Sustainability that's certified: Our aluminium profiles meet the key criteria of major building certifications and have played a clear role in helping these projects achieve certified status.

A wide range of products

Our offer of windows, doors, and facades has been designed with sustainability in mind - while also delivering long-lasting comfort, safety, and security for building users

Regulations and Certifications

Today, a building's sustainability is a key consideration for buyers, tenants, and investors. This is reflected in the growing number of certification schemes that assess environmental performance against clear standards.

With Cradle to Cradle labels, performance test reports, lifecycle assessments, and dynamic Environmental Product Declarations (EPDs), we provide the proof that our products meet the evolving expectations of the market.

75% Recycled 95% Recyclable

The production of primary aluminium from bauxite extraction requires large amounts of energy with current industrial processes. This results in significant CO₂ emissions and is a direct contributor to climate change. By recycling aluminium scrap after a product’s end-of-life, the remelting process saves up to 95% of that energy while delivering a material with the same high quality as primary aluminium.

Using Hydro CIRCAL reduces the environmental impact

The consequence of using Hydro CIRCAL is a drastic reduction in CO₂ emissions — more than 85% compared to the global average for primary aluminium production. With just 1.9 kg CO₂ per kg of aluminium, Hydro CIRCAL currently has one of the lowest carbon footprints of any aluminium alloy on the market.

And it doesn’t stop there. The goal is to reduce the footprint even further by using an alloy made from 100% post-consumer recycled aluminium scrap.

Would you like to know more?

Contact us and we’ll help you find the best solution for your project