Company commitment

We approach sustainability holistically, therefore, we go beyond products to reduce the upfront and embodied emissions of the building’s carbon footprint.

- 50% Reduction in CO2 Emissions Globally

- Packaging & Transport

- Workplace

SAPA and sustainability

At SAPA we believe we have the responsibility and the ability to tackle today’s and tomorrow’s most burning issue: climate change. Earth is warming, and it is caused by humans¹. This threatens every form of life and urgent action needs to be taken if we want our planet to survive.

Moreover, the world’s population is predicted to increase by 2 billion people in the next 30 years with a 70% of the population living in urban areas², which means at SAPA we will likely see a higher demand in the building and construction sector³. With more and more people living in buildings, this implies an increasing energy consumption and thus, skyrocketing CO2 emissions. The urge to rethink our products and processes has been even more challenging with growing pressure coming from regulations – from the European and international level with new norms and constraints for carbon neutrality; but also from national laws becoming more and more demanding⁴.

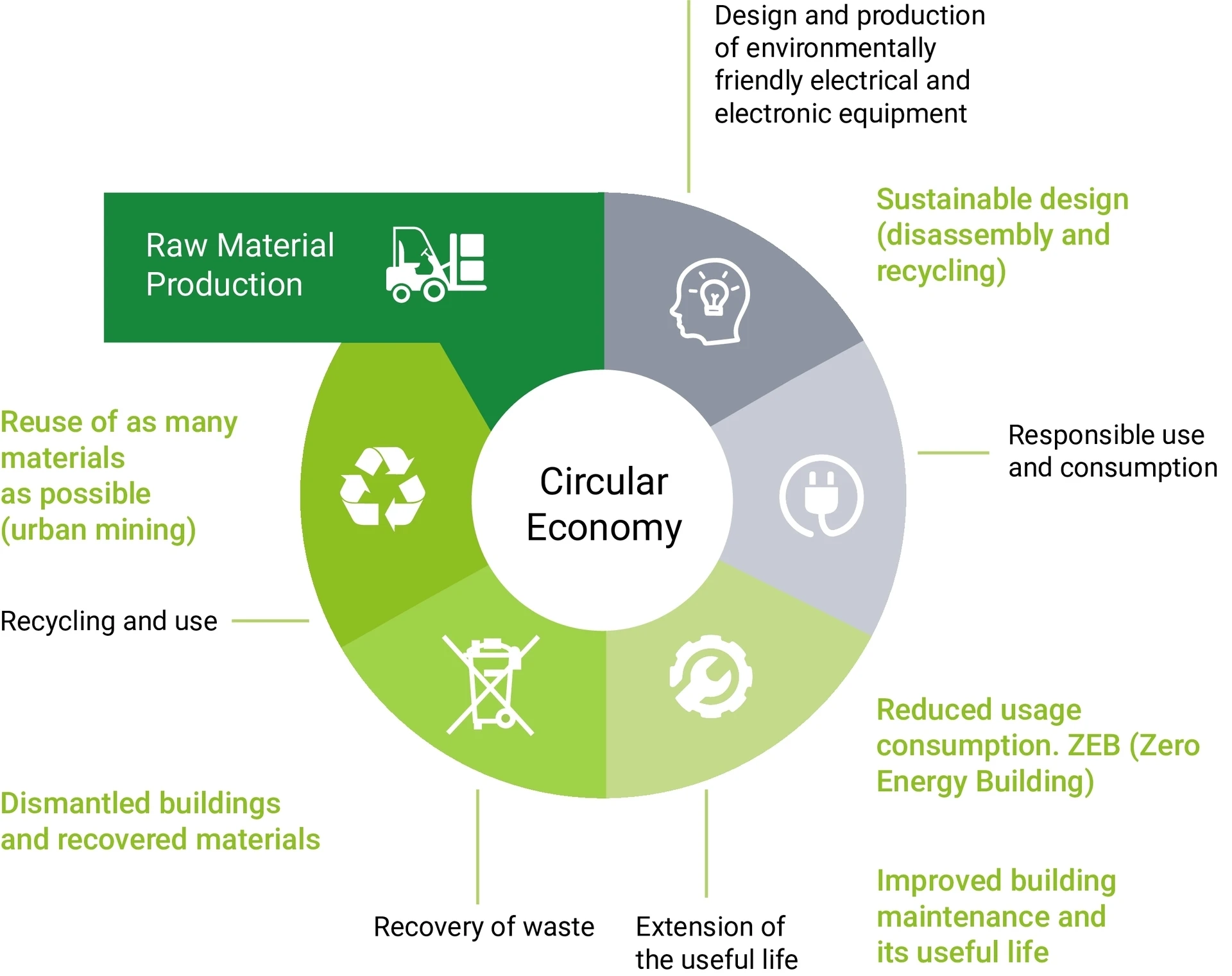

Circularity

The data is clear: 26% of non-residential buildings in Europe will need to be renovated by 2033.

Low-carbon renovation starts with three guiding principles: Sobriety, Circularity, and Anticipation.

We use recycled materials like aluminium, polyamide, and EPDM, and we design our products so they can be easily taken apart and recycled at the end of their life. Our goal? To shrink our environmental impact without compromising performance or quality.

And we don't do it alone. With support from our partners, we're scaling up - collecting end-of-life materials and turning them into new, sustainable solutions that can be recycled all over again.

We are closing the loop!

Our material

We are absolutely convinced that future urban development is inconceivable without reusing materials. Aluminium is the ideal choice: infinitely recyclable without losing its properties and low-maintenance, whether anodised or painted. With the sourcing of Hydro CIRCAL, a prime-quality aluminium made with a minimum of 75% recycled end-of-life aluminium, we anticipate regulations and reach the most demanding building certifications. Responsible sourcing: Beyond aluminum, all components are carefully selected for their environmental impact, and made from post-consumer recycled materials.

Our recyclable product

Circularity is key when it comes to further reducing product-related carbon emissions.

Our mission:

Design today light, performant and long lasting products easily dismantable and sortable for tomorrow

Make products with circular material to minimize the footprint and to reduce the waste of our industry

Ensure systems produced within a responsible supply chain and certified by external organisations for maximum traceability

Offer solutions to get ahead regulations, gain competitive edge and secure green financing

Challenges

We are all aware of the climate crisis and environmental problems that we all need to work together to solve. The lifecyle of products - from manufacture to obolescence - needs to be a priority when it comes to choosing certain products over others.

The aim of a circular economy is to start up new industrial processes that respond to these needs for recyclability and reuse of products. Many products manufactured that uphold these principles are now certified with the Cradle to Cradle seal.

SAPA in line with these guidelines and aims already has some aluminium building systems with the Cradle to Cradle distinction.

A buildings life cycle

The building and construction sector currently accounts for 39% of global energy-related carbon dioxide emissions. A building's carbon footprint can be divided into two stages: use (emissions caused by, for example, heating and cooling during the use phase) and construction (emissions caused by material extraction and production, delivery, waste management, etc.). The use phase represents 72% of a building's total carbon footprint, while construction and production account for 28%.