Genbrugte aluminium

Fra design til slutningen af livscyklussen, med fokus på høj ydeevne, genanvendelighed og minimal miljøpåvirkning.

- Øget levetid

- En cirkulær livscyklus

- Aluminium med lavt CO2-aftryk

Hydro CIRCAL® 75R som standard

Hydro CIRCAL® er vores lavkulstofaluminium, fremstillet med mindst 75 % genanvendt materiale fra forbrugerprodukter. Det betyder, at aluminiumet stammer fra produkter ved slutningen af deres livscyklus, såsom gamle facader eller vinduer, som genanvendes.

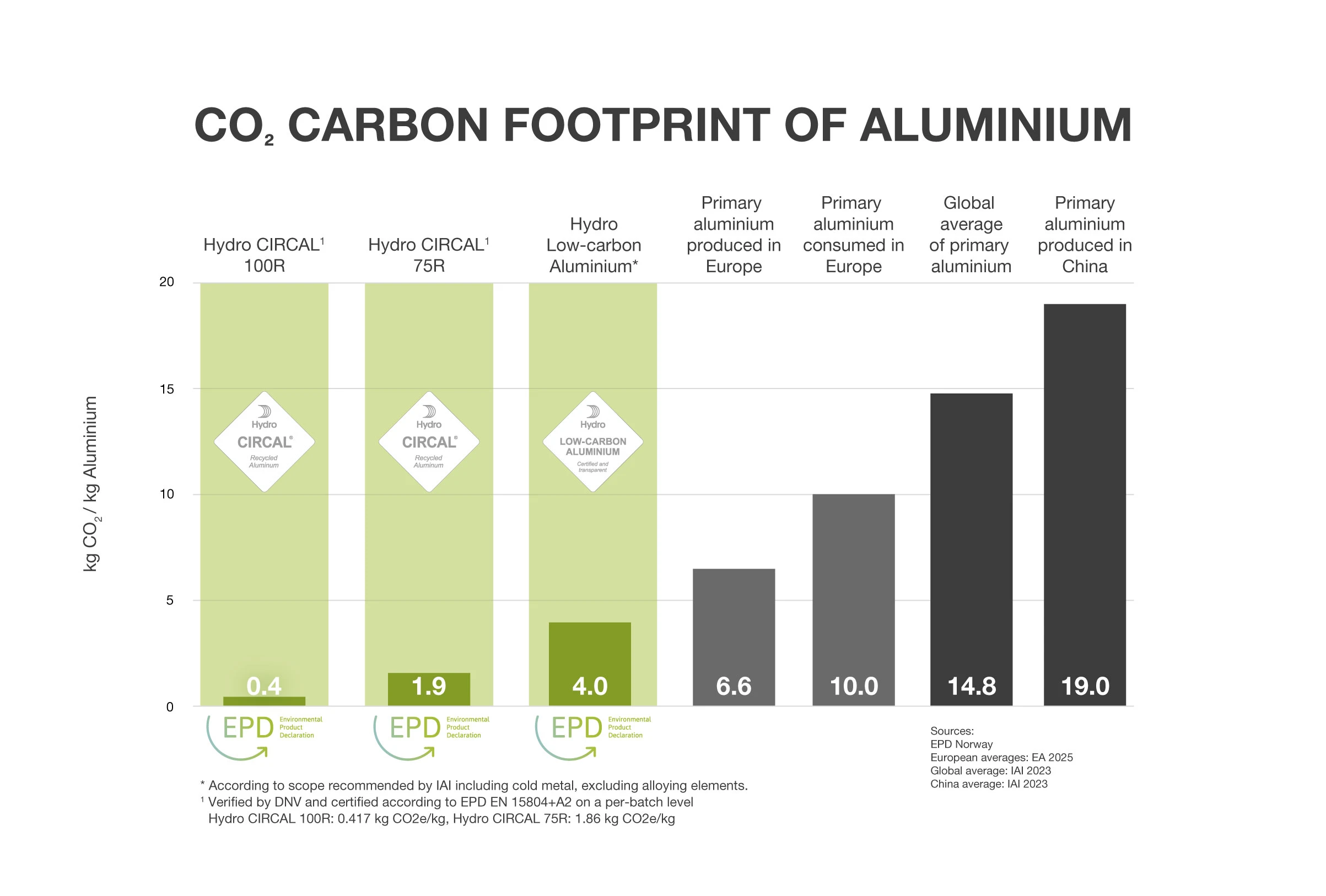

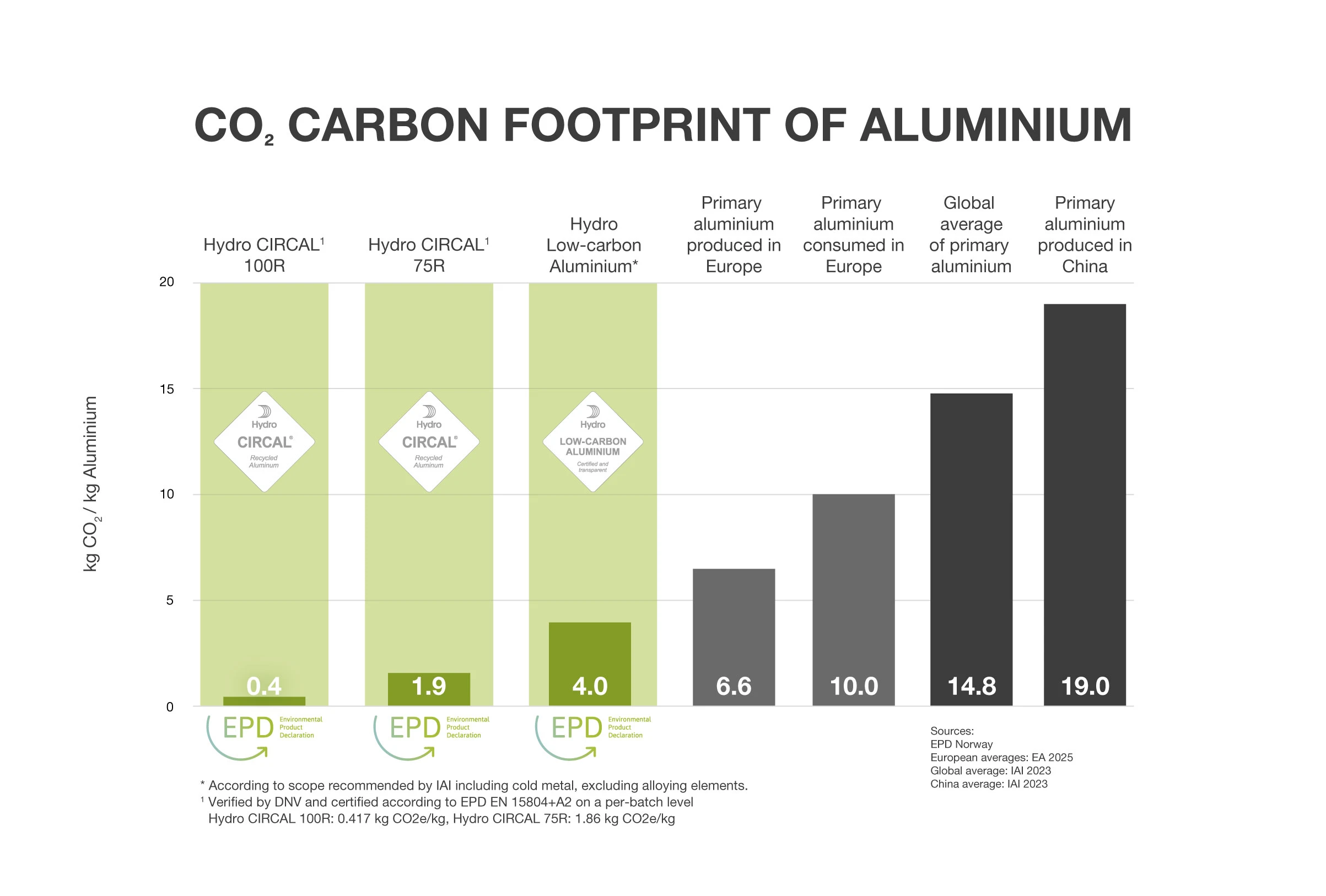

Hydro CIRCAL® 75R har et af verdens laveste CO₂-aftryk: 1,9 kg CO₂e pr. kg aluminium. Dette svarer til en reduktion på 80 % i forhold til det europæiske gennemsnit for primæraluminium. Produktion og råmaterialer i Hydro CIRCAL® 75R kan spores på individuelt batchniveau og leveres med en Environmental Product Declaration og verifikationsdokument. Med dette lavkulstofaluminium kan vi skabe byggematerialer af høj kvalitet, som er cirkulære og har lave emissioner, og som opfylder de højeste miljøstandarder.

Hydro CIRCAL® 100R, 100 % genanvendt, fås efter anmodning

Hydro CIRCAL® 100R er et gennembrud inden for bæredygtigt aluminium – fremstillet af 100 % genanvendt materiale fra forbrugerprodukter. Det er vores mest avancerede materiale, udviklet til projekter, hvor cirkularitet og reduktion af CO₂-udledning er højeste prioritet.

Med et uafhængigt verificeret CO₂-aftryk på under 0,5 kg CO₂e pr. kg aluminium tilbyder Hydro CIRCAL® 100R en reduktion på 97 % sammenlignet med det globale gennemsnit for primæraluminium (14,8 kg CO₂e). Det leverer førsteklasses ydeevne med et af de laveste CO₂-aftryk, der findes i verden.

På grund af den tekniske kompleksitet og den omhyggelige råvareindkøb produceres Hydro CIRCAL® 100R i øjeblikket i begrænsede, bestillingsbaserede partier – ideelt til fremtidssikrede projekter, der ønsker at opfylde de højeste miljøstandarder.

Vores produkter går ud over aluminium. Vi vælger omhyggeligt leverandører, som deler vores passion for kvalitet og bæredygtighed. Sammen skaber vi løsninger og produkter, der er tilpasset netop dit projekt.

Et lavere CO2-aftryk

At reducere bygningers CO₂-aftryk starter med deres design og materialer. Da en tredjedel af de samlede CO₂-udledninger sker i brugsfasen, er den mest effektive måde at reducere driftsudledninger på at tilbyde højtydende facadeløsninger, som optimerer energiforbruget over tid. Derfor designer vi facader, der leverer enestående termisk isolering, energieffektivitet, akustisk komfort og minimal vedligeholdelse.

Men det stopper ikke her — vores nye systemer er lavet med mindst 75 % genanvendt og 95 % genanvendeligt materiale, og er bygget til cirkularitet: nemme at demontere, genbruge og genanvende ved livscyklusens slutning. For at gå endnu længere sikrer vi, at vores systemer produceres inden for en ansvarlig forsyningskæde og er certificeret af eksterne organisationer — hvilket giver maksimal gennemsigtighed og ansvarlighed.

Ved at kombinere ydeevne i brug med lav-impact og cirkulære materialer opnår vores facader et CO₂-aftryk, der er op til 70 % mindre end sammenlignelige produkter.

VI ARBEJDER FOR BÆREDYGTIGHED

VI TAGER OS AF UDTJENTE PRODUKTER

VI DESIGNER HOLDBARE OG HØJTYDENDE PRODUKTER

VI BRUGER CIRKULÆRE MATERIALER

VI UNDERSTØTTER DINE PROJEKTER MED DE RETTE DIGITALE VÆRKTØJER

VI REDUCERER VORES PRODUKTERS AFTRYK

SAPA har løsninger til mere bæredygtigt byggeri

Certificeret bæredygtighed: Vores aluminiumprofiler opfylder de vigtigste kriterier for førende byggecertificeringer og har spillet en klar rolle i at hjælpe disse projekter med at opnå certificeret status

Et stort produktsortiment

Vores udvalg af vinduer, døre og facader er designet med bæredygtighed for øje – samtidig med at det sikrer langvarig komfort, sikkerhed og tryghed for bygningens brugere.

Regler og certificeringer

I dag er en bygnings bæredygtighed en vigtig faktor for købere, lejere og investorer. Det afspejles i det stigende antal certificeringsordninger, der vurderer miljøpræstationer ud fra klare standarder.

Med Cradle to Cradle-certifikater, præstationstests, livscyklusvurderinger og dynamiske miljøvaredeklarationer (EPD'er) leverer vi dokumentation for, at vores produkter lever op til markedets voksende forventninger.

75 % genanvendt, 95 % genanvendeligt

Fremstilling af primæraluminium fra bauxitudvinding kræver store mængder energi med de nuværende industrielle processer. Dette fører til betydelige CO₂-udledninger og er en direkte årsag til klimaforandringer. Ved at genanvende aluminiumskrot efter et produkts levetid sparer omsmeltningsprocessen op til 95 % af denne energi og leverer et materiale med samme høje kvalitet som primæraluminium.

Ved at bruge Hydro CIRCAL mindskes klimaaftrykket

Konsekvensen af at anvende Hydro CIRCAL er en markant reduktion af CO₂-udledningerne — med mere end 85 % sammenlignet med det globale gennemsnit for produktion af primæraluminium. Med sine 1,9 kg CO₂ per kg aluminium er Hydro CIRCAL i øjeblikket en af de aluminiumlegeringer med det laveste CO₂-aftryk på markedet.

Og det stopper ikke her. Målet er at reducere aftrykket endnu mere og bruge en legering, der består af 100 % genanvendt aluminiumskrot.