Ett komplett transportsystem av högsta kvalité

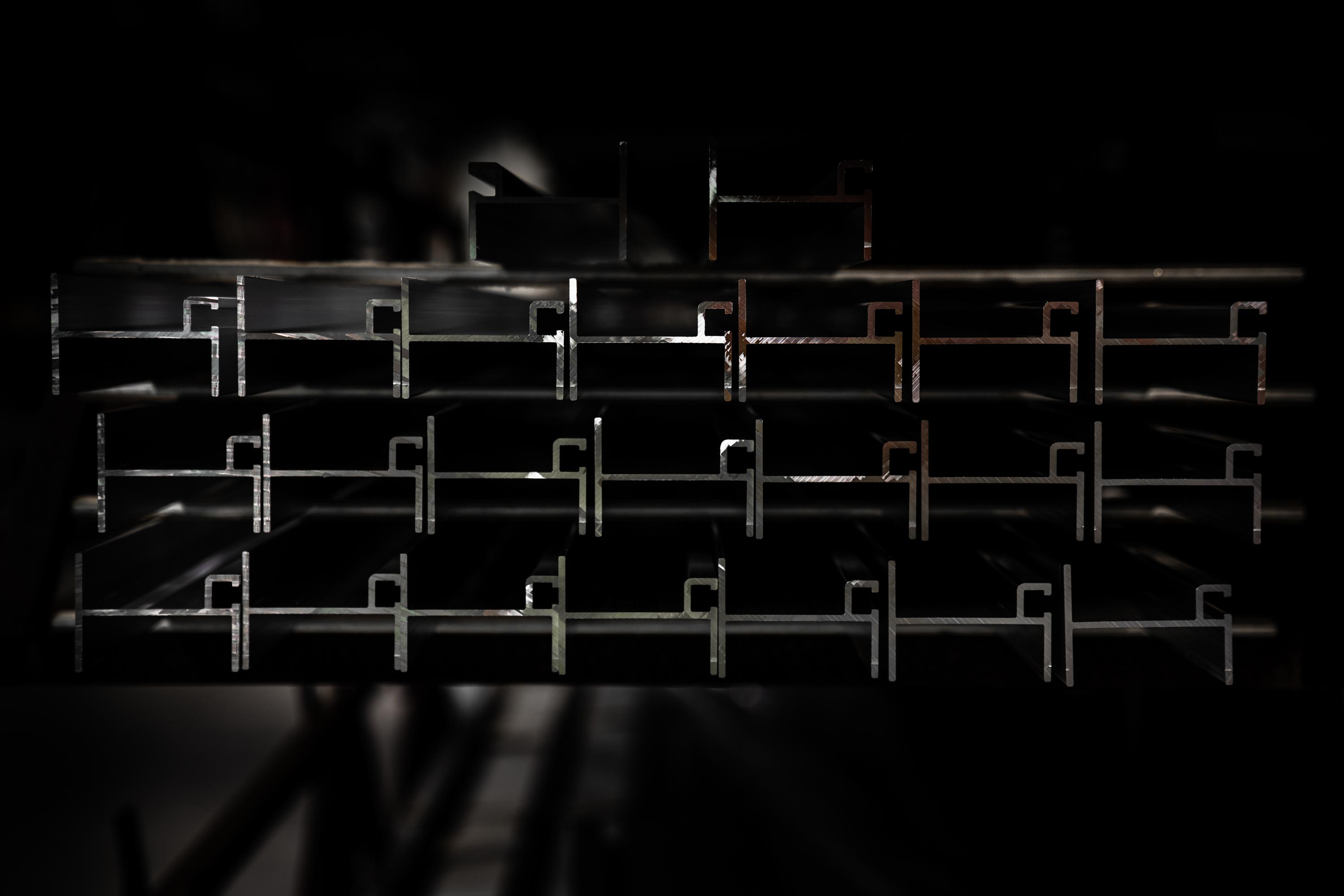

Sapas transportsystem är som en precisionsbyggsats för lastbilspåbyggnad. Vi erbjuder ett brett sortiment av aluminiumprofiler och tillbehör som kombineras ihop för att kunna tillverka flak och lämmar till styckegods, samt tipp och skåpbyggnationer för såväl släpvagnar som lastbilar.

Aluminium – det utmärkta valet

Som aluminiumexperter vet vi hur vi kan använda materialets egenskaper på bästa sätt för att erbjuda innovativa och kvalitativa produkter. Aluminium är en stark och lätt metall som kan formas till önskad geometri för att tillverka moderna och avancerade lösningar som är lätta att använda.

Sapa – en del av Hydro

Hydro är ett globalt, helt integrerat aluminiumföretag med 31 000 medarbetare.